Vacuum Chamber

3 min read

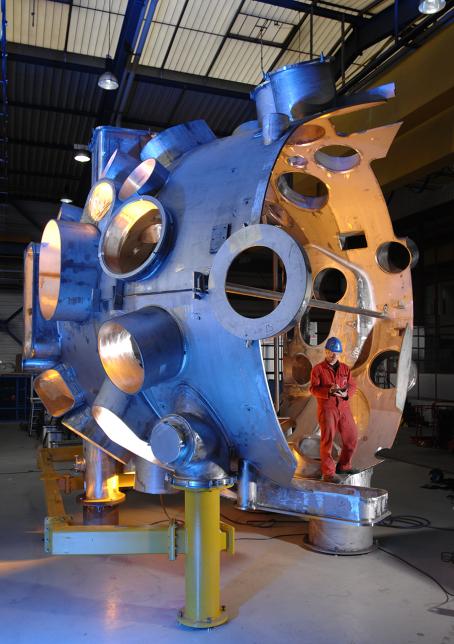

Since stellarator plasma has the shape of a twisted ribbon with a changing bean-like cross-section, the vacuum vessel that encloses it also has a strange and irregular shape. You can imagine it like a hollow steel donut that has been randomly squashed by a giant hand in some places.

Shape

The exact shape of the vacuum chamber depends on the type of magnetic configuration each device uses. The chamber is slightly more symmetrical for those with helical winding around the torus (e.g. heliotrons) than for those with modular coils (e.g. modular stellarators), but still more complex than a simple torus. Magnetic coils are placed very close to the vacuum vessel, and between them there is only limited space for access to the vessel. This is ensured by ports, which protrude from the vessel like hedgehog thorns. They are used for heating, maintenance, diagnostics, vacuum pumps, or gas piping.

Heat Load

The plasma temperature inside the vacuum vessel reaches 100 million kelvin and is insulated from the vessel wall by a magnetic field only. So, the vessel has to be constructed to sustain high thermal loads during operation (similar to the heat load experienced by spacecraft re-entering the Earth’s atmosphere). The main body of the vessel is stainless steel with carbon tiles inside. The active water cooling of tiles is necessary in modern stellarators. Part of the vessel is lined with divertor plates, beneath which the vacuum pumps are located. Magnetic field lines direct impurities toward the divertors.

Cryostat

While plasma has a temperature of 100 million kelvin, magnetic coils located nearby must maintain their superconductivity at only 4 kelvin. To minimize heat transfer from plasma to coils, the outer side of the vessel used to be actively cooled and covered by thermal shield insulation. To minimize heat transfer even more, a vacuum is maintained in the space between the vessel and the coils. This is ensured by an outer vessel called a cryostat, which is in fact a very large and sophisticated thermos and encapsulates the vacuum vessel and coils.

Future Shielding

Deuterium-tritium fusion has not taken place at any stellarator yet. To be prepared for that, stellarators need to first install proper neutron shielding between the plasma and vessel wall or coils. This shielding will also serve in a power plant as a tritium breeder, capturing neutrons in lithium and producing desirable fuel — tritium. But for best operation, the shielding with incorporated breeders has to be about 1 metre thick. This will push magnets away from the vessel and will lead to the need for stronger magnets and bigger machines.