How it Will Look Like

5 min read

A lot of countries are developing their own concepts of the first demonstration fusion power plant.

Fission Plants Inspiration

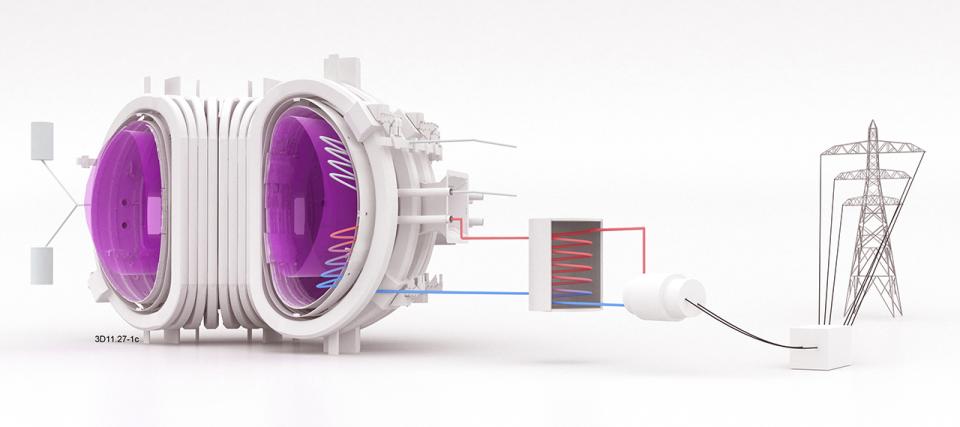

The thermonuclear power plant could be divided into two major parts. One is the reactor part, where the heat is generated by thermonuclear fusion, and the second one is the turbogenerator part, where the heat is transformed into electricity. If the reactor operated continuously, the non-reactor part would be essentially the same as in any other thermal plant. A lot of DEMO designs are calculated with PWR (pressurized water reactor) technology used in fission plants where pressurized water around 320 °C transports heat from the reactor to the steam generator. The hot steam from the steam generator is routed by a secondary circuit to the turbine. A multistage turbine propels a generator that generates electricity. The efficiency of heat-to-electricity conversion is about 33 percent, which seems low, but this is the best way to convert heat to electricity ever invented.

Thermal Storage

The tokamak principle is used in all current designs of demonstration fusion power plants. But because the tokamak is a pulse device, it is possible that the reactor will not be able to operate continuously, at least in the early phases. In such a case, the heat storage tank would have to be incorporated between the reactor and the steam generator. The thermal storage filled, for example, with molten salts will accumulate heat during the fusion reaction and release it continuously toward the steam generator.

Large Magnets

The power plant tokamak has to be even bigger than the experimental reactor ITER. The major radius of the DEMO plant varies from 6.8 m of Korean K-DEMO to 9.0 m of EU-DEMO. The vessel will be about 15 metres high. For the central solenoid, toroidal and poloidal coils, superconducting magnets will be used. Larger coils mean higher magnetic fields. The material that retains its superconductivity even in such a high field is niobium-tin (Nb3Sn). The ITER tokamak is gaining experience in manufacturing coils from this extremely brittle material. Although high temperature superconductors like ReBCO can be used because they are easier to work with and keep their properties in temperatures up to 70 kelvin, they are not planned in the present DEMO designs. The experience with their usage is still insufficient, but they can be used later in the second phases of DEMO projects.

Tritium Breeders

The exact construction of the coils, especially toroidal coils, is the subject of intensive research and development because they will have to sustain enormous stress during operation. Between the coils and the plasma, there will be more space than in current tokamaks. The extra space is needed for tritium breeders’ replacement. Except EU-DEMO, which has not decided on the type of breeder yet, all other designs plan to use solid breeders filled with lithium and neutron multiplier pebbles. JA-DEMO designed breeders with a complicated honeycomb structure. In each hexagonal compartment, there will be cooling pipes and a mixture of Li2TiO3 and Be12V pebbles. In K-DEMO, there will be a mixture of Li4SiO4 and Be12Ti pebbles. The breeder will be extracted once a year through the large upper port and replaced by a fresh one. The tritium building will be situated close to the reactor where tritium will be separated from breeders. A radioactive waste storage pool will also be situated there. The used radioactive breeders will be stored under water for ten years.

Divertor

Most designs calculate with a divertor on the bottom part of the vessel (a configuration called single-null-divertor), except K-DEMO, which wants to use two divertors, the second one in the upper part of the chamber (double-null-divertor).

Inputs and Outputs

The thermonuclear power plant will have to be equipped with a large cryoplant that will ensure a continuous supply of liquid nitrogen and helium for superconductive coils cooling. The nitrogen and helium storage will be placed in an areal as well as deuterium storage. The breeders will probably be transported into the power plant from the factory, but extremely large coils will be wound in an on-site facility. The “waste” from the fusion plant will be the technical gas helium.