The Future of Fission Reactors

7 min read

Generation I nuclear reactors were developed in 1950—1960 and except for a few operating reactors in Great Britain, they have all been decommissioned. The majority of the existing reactors are Generation II reactors developed in the 1970s. Generation III reactors are actually modernizations of the existing reactors. They were simplified and their safety features were improved. These reactors are already under construction or in planning. Generation IV reactors should be ready by 2020.

Generation III Reactors

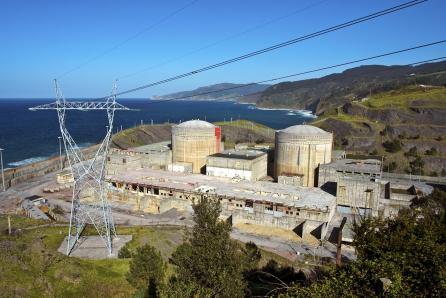

The Lemoniz nuclear power plant in Spain has never been completed. Construction of two blocks with PWR reactors was halted in 1983 due to the changed government’s nuclear policy caused by ETA’s terrorist attacks.

This new generation of modernized nuclear reactors has a simpler design leading to their simpler, cheaper, and faster construction. At the same time, their advantages include: improved operating safety, higher energy yield from the same amount of nuclear fuel, and simpler operation. These power plants also employ the so-called inherent safety elements. In case of accidents, there is no need for an electronic intervention or an operator’s action. Safety is provided based on the laws of physics: gravitation, heat flow and material resistance against high temperature. The life cycle of Generation III reactors is extended to at least 60 years. These power plants are able to react more flexibly to grid demands and they regulate their power output better. In theory, some of the PWR type reactors could increase their power output from 25% power to full power in less than 30 minutes although at the cost of an increased structural loading. Many reactors have been improved, e.g., the AP 1000, the Westinghouse improved PWR type reactor, the EPR (European pressurized water reactor), the Areva improved PWR type reactor, and the modernized boiling water reactor ABWR (advanced boiling water reactor) made by GE-Hitachi and Toshiba.

Generation IV Reactors

Currently, there are six types of Generation IV reactors under development. All of them will operate at higher temperature and four reactors will use fast neutrons for fission. The high temperature will be used both for the generation of electricity and for the thermochemical production of hydrogen.

Gas Cooled Fast Reactor (GFR)

A mixture of depleted uranium and about 15%—20% plutonium is the fuel for this type of reactor. It is a pin or plate-based fuel with circulating helium. The peak temperature is about 850 °C. There is no breeding envelope: plutonium is produced by neutron capture directly inside the fuel (fast unmoderated neutrons are used for fission). The helium may be supplied to a turbine directly. A power plant with three loops would have a power output of 1,200 MWe. Radioactive waste would be reprocessed directly within the power plant premises.

Lead Cooled Fast Reactor (LFR)

This reactor will be fueled by uranium or thorium mixed with actinides in the form of a metal or a nitride. The coolant, circulated at low pressure by natural convection, is lead or a mixture of lead and bismuth. The exit temperature is about 550 °C. However, it can be increased up to 800 °C if new materials that will resist the high temperatures and the lead-induced corrosion are developed. Various sizes of power plants are anticipated ranging from small “batteries” of approximate power output 300 MWe up to large power plants of power output 1,400 MWe.

Molten Salt Cooled Reactors (MSR)

Uranium will be dissolved in the coolant itself (sodium fluoride salt) that will be circulated in graphite channels used as the moderator. Thanks to this arrangement, the reactor can be refueled during operation and the fission products can also be filtered out from the coolant during operation. There is no need to handle spent nuclear fuel and a direct recycling of actinides is also possible. The reactor core temperature is about 700 °C and the anticipated power output is 1,000 MWe.

Two blocks of the Bellefonte nuclear power plant in Alabama, USA, have been under construction for more than 20 years. Any interruption of the construction always brings about an increased cost due to the needed design updates and equipment modernization.

Sodium Cooled Fast Reactor (SFR)

This reactor type is based on the existing fast sodium cooled reactor. The fuel is a mixture of depleted uranium and actinides. The coolant is molten sodium. Due to safety concerns, there will be two sodium circuits and the tertiary circuit will be the water circuit. The temperature on reactor exit is 500 °C. Construction of various size power plants ranging from 50 MWe up to 1,500 MWe is anticipated.

Supercritical Water Reactor (SCWR)

Supercritical ordinary water at high pressure and temperature exceeding the thermodynamic critical point of water (at 374 °C, 22 MPa) will be used as both the moderator and the coolant for this reactor. At a pressure of 25 MPa and temperature 510—550 °C, this power plant exhibits high thermal efficiency. Water exiting the reactor will directly drive a turbine.

High Temperature Gas Cooled Reactor (HTGR)

Video: Model of the gas-cooled Allegro reactor.

The Small Sealed Transportable Autonomous Reactor (SSTAR) is a fission reactor project using fast neutrons for fission. It is cooled by a eutectic alloy of lead and bismuth, has an operating temperature of about 560 °C, and has passive safety systems. A unit of 10—100 MWe power output could be transported by train and could operate for 20 years without refueling.