Pelton Turbine

3 min read

Lester Allan Pelton

5. 9. 1829, Vermilion, Ohio, U.S.

14. 3. 1908, Oakland, California, U.S.

Lester Pelton was an American inventor specialized in the field of electric power generation with a focus on turbines. During his time in California, Pelton designed a water wheel with very specific shaped buckets. When the wheel was about to be started, the water stream hit only the outer rim of the buckets by accident. The immediate and violent increase in the speed of the wheel, within a moment, led to its destruction. When analyzing the cause of this phenomenon, Pelton discovered that the motion energy of a water jet is best captured by spoon-shaped buckets if the water jet is directed along a tangent to the path of the runner. He patented his turbine in 1880.

Pelton Turbine

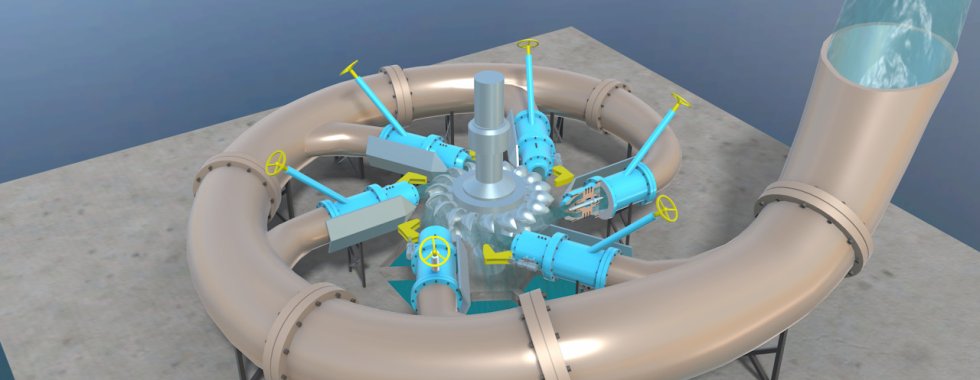

The Pelton turbine is an isobaric impulse action turbine with water flow tangential to the path of the runner. The term isobaric means that the water that goes into the runner buckets has the same pressure as the water leaving them.

The water coming from the penstock with a circular cross section is led into nozzles which direct the water jet tangentially to the spoon-shaped buckets on the runner. Inside the nozzle, the pressure of the entire head is transformed into kinetic energy. The water jet is split in half by a ridge in the bucket which effectively turns the stream around, and since water is almost incompressible, it gives away almost all its energy. Due to the balanced speeds of the jet water and the rotation of the runner, water leaves the turbine at a minimal residual speed.

The turbine power output is regulated by narrowing or widening the nozzle by inserting a regulating needle. When quick power output reduction or a complete power down of the turbine is required, the water is simply diverted away from the runner.

The efficiency of smaller Pelton turbines lies between 80 and 85%, while larger turbines, provided there is high enough water pressure, may reach up to 95%. The turbines are produced in horizontal as well as vertical variants for hydraulic heads from 30 to 1,800 meters with a unit capacity of up to 200 MW. This is why they are so often used in power plants with a very high hydraulic head, typically in mountainous regions like Austria or Switzerland. Depending on the rate of flow, up to three nozzles are used in horizontal and up to six in vertical Pelton turbines.