Small Modular Reactors

26 min read

If you are interested in how a nuclear power plant with Small Modular Reactors may look, you can explore its online 3D model in the “3D Models” section or download the embed code for integration into your own website from the “Free Downloads” section.

Introduction/Overview

Small Modular Reactors (SMRs) are a new generation of nuclear fission reactors designed to deliver reliable, low-carbon energy in a more flexible and scalable way. Each module typically produces up to about 300 megawatts of electricity, which is significantly less than conventional large reactors. Their compact size and modular design allow the main reactor components to be manufactured in a factory, transported to the site, and assembled more efficiently than traditional plants.

A nuclear power plant equipped with several small modular reactors can supply reliable energy for entire industrial-scale urban areas.

SMRs are intended to complement both large nuclear power plants and renewable energy systems. They can provide steady baseload electricity or be operated flexibly to support variable renewable generation. Owing to their smaller footprint and simplified systems, SMRs are suitable for remote locations, smaller grids, or industrial sites where large reactors would be impractical.

In the broader context of global decarbonisation and energy diversification, SMRs are viewed as one of the most promising options for expanding the role of nuclear energy while maintaining high safety standards and reducing investment risks.

Characteristics

The defining feature of SMRs lies in their modularity. Each unit is designed as a self-contained system that can operate independently or as part of a multi-module plant. This approach enables utilities to add capacity gradually as demand or financing allows. Factory production of modules shortens construction times, improves quality control, and reduces the risk of cost overruns.

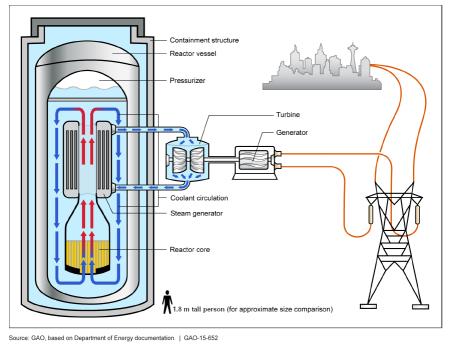

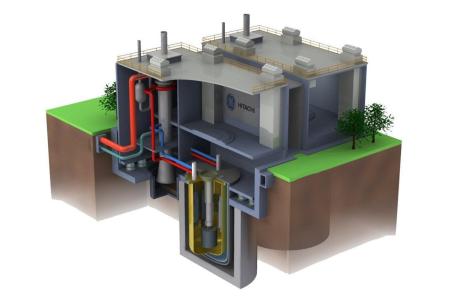

Simplified schematic representation of the connections between key components in a small modular reactor power plant.

SMRs are also characterised by simplified and compact reactor systems. In many designs, the reactor core, steam generator, and pressuriser are housed within a single pressure vessel, reducing the number of external connections and potential failure points. Advanced passive safety mechanisms — such as natural circulation cooling, gravity-fed emergency systems, and large thermal inertia — allow SMRs to maintain safe shutdown conditions without the need for active intervention or external power.

Compared to conventional reactors, SMRs have a smaller exclusion zone and require less cooling water, which broadens the range of potential installation sites. The combination of modularity, enhanced safety, and scalability makes SMRs a versatile solution for future nuclear energy deployment.

Applications / Use Cases

Small Modular Reactors (SMRs) are designed for a variety of energy applications beyond conventional electricity generation. Their compact size, flexible operation and ability to provide both heat and power make them suitable for various energy markets and industrial uses.

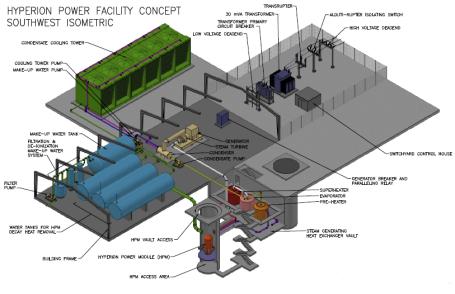

This illustrative 3D vision of a small modular reactor power plant suggests that such facilities could be compact and relatively simple in their overall layout.

The main use of SMRs is electricity production — either as single units for remote or regional networks, or as multi-module plants that can be expanded in stages as demand increases. This scalability enables flexible investment and gradual deployment of nuclear capacity.

SMRs can also supply process heat and cogeneration for industrial operations, district heating, or desalination. The stable and high-temperature heat output from certain designs, particularly high-temperature gas-cooled reactors (HTGRs) and molten salt reactors (MSRs), allows them to be used for hydrogen production through high-temperature electrolysis or thermochemical cycles.

Their long refuelling intervals, simplified operation, and transportable design make SMRs well suited for remote mining facilities, island power systems, and other off-grid applications where reliable energy supply is essential.

Historical Background / Development

The concept of small modular reactors has its roots in early nuclear technology used for submarines, icebreakers, and research reactors, where compact and reliable power sources were essential. In the following decades, advances in materials, passive safety systems, and modular manufacturing revived interest in small-scale nuclear plants as a complement to large commercial reactors.

The NRC’s five Commissioners met as a full Commission during a public meeting in Rockville, Maryland, to discuss regulatory issues related to small modular reactors.

Several SMRs are now either operating or approaching deployment. Russia’s Akademik Lomonosov, using two KLT-40S reactors, has been supplying power and heat to the Arctic port of Pevek since 2020. China’s HTR-PM, a high-temperature gas-cooled reactor, achieved first grid connection in 2021. Other projects such as NuScale (USA), SMART (Korea), CAREM-25 (Argentina) and ACP100 (China) are in advanced stages of design, licensing, or construction, marking the transition of SMRs from experimental concepts to commercial reality.

Designs and Architectures

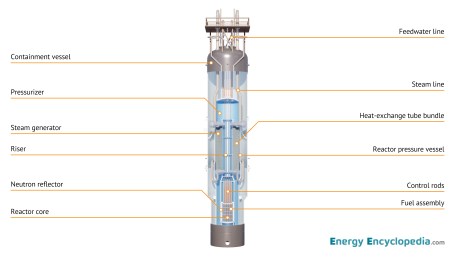

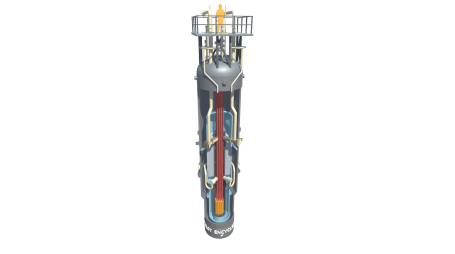

The illustration shows a typical configuration of integral light-water small modular reactors, with the primary system housed inside the reactor pressure vessel and connected to a conventional secondary loop.

SMRs cover a wide range of reactor configurations that differ in both technological design and overall plant architecture. Most concepts adapt proven reactor technologies to smaller, modular units that can be built in factories and transported to the installation site. The guiding principle is design simplification — reducing system complexity, enhancing safety, and enabling standardized, repeatable manufacturing.

From the technological standpoint, the primary circuit can be arranged in two main ways. In integral designs, all major components of the primary loop — the reactor core, steam generator, pressuriser, and circulation pumps — are contained within a single pressure vessel. This minimizes external piping, reduces the risk of coolant leakage, and improves inherent safety. In loop-type designs, these components are located outside the reactor vessel and connected by piping, which allows easier access for inspection and maintenance and can be advantageous for certain high-temperature or fast-spectrum systems.

If you are interested in the construction of a small pressurized water reactor module, you can view its 3D model online in the “3D Models” section or download the embed code for use on your own website from the “Free Downloads” section.

At the plant level, SMRs can operate either as independent modules, each with its own secondary circuit and turbine system, or as part of a shared-infrastructure configuration, where several reactor modules feed a common secondary system such as a turbine hall or cooling network. Independent modules allow flexible operation and simple isolation for maintenance, while shared configurations reduce capital costs and improve overall efficiency through economies of scale.

Technologies

Small Modular Reactors employ several reactor technologies that differ mainly in the type of coolant, neutron spectrum, and operating temperature. These factors determine efficiency, safety features, and the range of potential applications — from electricity generation to industrial heat and hydrogen production.

The principal product envisioned by the private U.S. company Gen4 Energy, Inc. was the Hyperion Power Module, a compact small modular reactor with an electrical output of approximately 25 MW, intended primarily for smaller or remote locations.

The most common SMR designs are water-cooled reactors, derived from conventional light-water technologies such as pressurised and boiling water reactors. They rely on proven materials and operational experience, providing a well-understood regulatory path. With outlet temperatures around 300 °C, they are well suited for electricity generation and low-temperature heat applications.

High-temperature gas-cooled reactors (HTGRs) use helium as coolant and graphite as moderator, reaching outlet temperatures above 700 °C. Their high thermal efficiency and stable operation make them attractive for cogeneration and hydrogen production through high-temperature electrolysis or thermochemical cycles.

The technology of small modular liquid-metal-cooled fast reactors was partially derived from earlier systems, including the Monju fast breeder reactor.

Liquid metal-cooled reactors, typically using sodium or lead, operate at near-atmospheric pressure and elevated temperatures. Their excellent heat transfer properties and, in most designs, fast neutron spectrum enable high thermal efficiency and effective fuel utilization. These systems are also suitable for closed fuel cycles and the recycling of nuclear materials.

Molten salt reactors (MSRs) employ liquid fluoride or chloride salts as coolant and, in some concepts, as fuel carrier. They operate at low pressure with strong negative temperature coefficients, offering inherent safety and enabling flexible fuel cycles, including the use of thorium.

Several SMR concepts also incorporate supercritical CO₂ or gas turbines to achieve compact layouts and improved efficiency. Many designs are intended for cogeneration, providing both electricity and high-grade heat for industrial processes, district heating, or desalination.

Nuclear Fuel and Fuel Cycle

Some water-cooled SMRs use standard fuel assembly formats, but with shorter assemblies and a substantially smaller number of assemblies in the core.

Small Modular Reactors use a range of nuclear fuels depending on their design and neutron spectrum. Most water-cooled SMRs employ low-enriched uranium dioxide similar to that used in large reactors, typically enriched up to about 5% 235U. Some advanced concepts use slightly higher enrichments — up to around 10% 235U — to extend refuelling intervals and simplify fuel logistics.

High-temperature gas-cooled, fast-spectrum, and molten-salt SMRs may operate with enrichments up to 20% 235U, the upper limit for low-enriched uranium. These designs often use alternative fuel forms such as metallic alloys (U-Zr, U-Mo) or TRISO-coated particles, which provide superior fission-product retention and high-temperature stability.

High-temperature modular reactors can employ alternative TRISO fuel, similar to that used in other high-temperature reactor designs. You can download the composition of a spherical fuel pebble for HTGRs from the Free Downloads section.

SMRs are typically designed for long operating cycles — from several years to decades — and some allow partial fuel recycling or closed-cycle operation, improving resource utilisation and reducing long-term waste. Several concepts also explore the thorium fuel cycle as an alternative route to enhance sustainability and fuel diversity.

Engineering and Project Challenges

Although Small Modular Reactors offer many potential advantages, their development and deployment also face a number of technical, industrial, and regulatory challenges. A key engineering task lies in translating modular design concepts into fully manufacturable products. Factory fabrication of large reactor components requires new production facilities, qualified supply chains, and precise quality assurance to meet nuclear standards. The transportation of heavy, prefabricated modules to remote or constrained sites also demands specialised logistics and infrastructure.

One of the challenges will be the transport of prefabricated modules from the manufacturing facility to the plant site, including the associated security measures and overall logistics.

Another important challenge involves licensing and regulatory frameworks. Most national regulations were originally developed for large light-water reactors, and adapting them to modular, non-traditional designs can be complex. Each new reactor type may require additional safety demonstration, material qualification, and testing of selected systems, which can extend approval timelines and increase costs. International cooperation among regulators is therefore essential to harmonise requirements and enable wider SMR deployment.

Illustration of a small modular reactor showing all major primary-circuit components integrated within the reactor pressure vessel. The image can be downloaded from the Free Downloads / Images section.

On the economic and project side, SMRs must prove that their modular approach can offset the loss of economies of scale typical for large reactors. Achieving competitive costs depends on standardisation, serial production, and learning effects across multiple projects. Managing early-stage investment risks, establishing reliable supply chains, and ensuring public acceptance remain crucial for moving SMRs from prototype to commercial reality.

Advantages of SMRs

Small Modular Reactors provide several advantages that stem from their reduced scale, simplified architecture and modern design approaches. Their compact systems and lower overall thermal output make them easier to cool in both normal operation and emergency situations, contributing to a high level of inherent safety. Many SMRs operate at lower system pressures or use coolants with favourable thermal characteristics, which further reduces the likelihood and consequences of loss-of-coolant events. These features allow safety functions to rely more on passive physical processes and less on active equipment, improving reliability and resilience.

An illustration showing the integration of multiple small modular reactors within a future nuclear power plant.

From an implementation standpoint, SMRs support flexible and incremental deployment. Smaller unit sizes reduce the financial commitment required to start a project, making nuclear generation more accessible to countries or regions with limited grid capacity or smaller energy markets. Modular construction and factory fabrication have the potential to shorten build times and increase predictability in costs and schedules. In addition to electricity, many SMR concepts can supply valuable non-electric services such as industrial steam, district heating or high-temperature heat for hydrogen production, allowing them to serve multiple roles within future low-carbon energy systems.

Nuclear Safety and Regulatory Aspects

Safety concepts in Small Modular Reactors are shaped by the aim to simplify plant architecture and reduce the number of systems that could initiate or aggravate an accident. Because SMRs operate with smaller reactor cores and reduced decay heat, many designs can meet key safety functions — such as long-term cooling or reactivity control — through physical processes that do not rely on active components or external power. This approach strengthens resilience across a wide range of conditions and decreases the complexity of emergency procedures.

Cross-sectional illustration of the Toshiba 4S (Super Safe, Small and Simple) micro sodium-cooled nuclear fission reactor design.

Many SMR concepts introduce features that influence how safety is assessed. These include below-grade installation of reactor modules, integral primary systems with fewer penetrations, and in some designs, long operating cycles without on-site refuelling. Such characteristics require safety evaluations that take into account extended passive heat removal, long-term containment performance, and the behaviour of novel materials during off-normal conditions. The increased use of digital instrumentation and automated control also calls for specific verification methods to ensure cyber security and reliable operation under fault conditions.

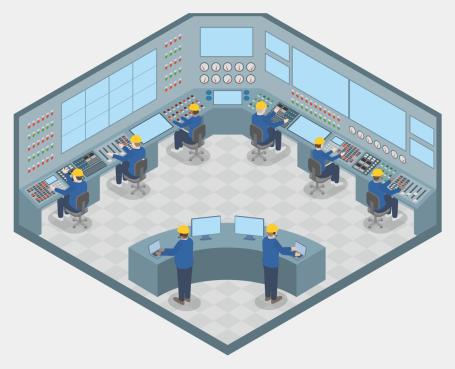

From a regulatory perspective, SMRs raise questions that go beyond those traditionally addressed for large reactors. Multi-module plants require clear rules for staffing levels, control room configuration, and the management of shared auxiliary systems. The possibility of reduced emergency planning zones — often discussed for SMRs with very low potential source terms — must be supported by robust source-term modelling and independent assessment. Designs intended for remote regions or industrial sites need to demonstrate that safety functions can be maintained even with limited local infrastructure or reduced on-site staffing.

Each module in a multi-module nuclear power plant will be operated independently from a shared control room, which will also host the controls for common auxiliary systems.

Some concepts introduce additional regulatory dimensions. Transportable or factory-fuelled units involve safeguards, security, and accountability measures across several jurisdictions. High-temperature, fast-spectrum, or molten-salt systems may require new qualification pathways for structural materials, coolant chemistry control, or fuel handling. Developers and regulators are therefore working toward streamlined, technology-neutral principles that can accommodate innovative reactor types while ensuring that SMRs maintain the high safety standards expected of nuclear installations.

Economics and Deployment Prospects

The construction of a nuclear power plant with a small modular reactor significantly enhances the energy security and self-sufficiency of a region while having only a minimal impact on the surrounding environment.

The economics of Small Modular Reactors depend largely on their ability to leverage factory fabrication, standardised designs and repeatable construction processes. While individual modules require smaller upfront investment than large reactors, their overall cost competitiveness — often expressed through the levelized cost of electricity (LCOE) — relies on achieving sufficient production volumes to realise economies of series. Early units may be more expensive, but learning effects, streamlined assembly, and stable supply chains are expected to reduce costs as deployment progresses.

Financing models play a key role in bringing SMR projects to market. Several countries are exploring public–private partnerships, state-backed financing, and export credit support to lower investment risks and enable first-of-a-kind deployments. These mechanisms can help bridge the gap between initial demonstration units and commercial-scale production, where modular construction is expected to deliver more predictable schedules and improved cost control.

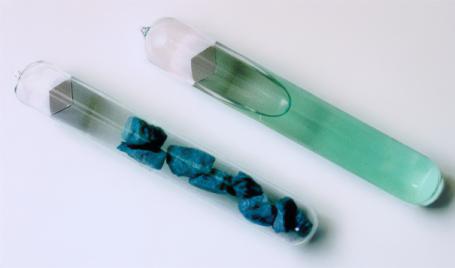

A graphite sphere containing dispersed micro-particles of nuclear fuel is used in so-called pebble-bed high-temperature reactors.

Deployment prospects for the 2030s are strongest in regions with clear policy frameworks and active development programmes. The United States, Canada, the United Kingdom, China and South Korea are among the leading markets, with multiple designs advancing through licensing, demonstration or early construction. Beyond electricity supply, SMRs capable of providing industrial heat or hydrogen production could further expand market opportunities, positioning them as a complementary option alongside large reactors and variable renewable energy sources.

Notable SMR Projects (by Technology Type)

Water-cooled SMRs

Water-cooled small modular reactors are the most advanced toward commercial deployment, as they build on proven light-water technology and established regulatory frameworks. Their modular construction and simplified systems enable flexible, incremental capacity additions.

The integrated reactor design of the ACP100, developed by China National Nuclear Corporation, enables all major primary-system components to be installed within the reactor pressure vessel.

NuScale VOYGR (USA)

An integral pressurised water reactor producing 50—77 MWe per module. The design relies on natural circulation in the primary loop and extensive passive safety features. NuScale has completed regulatory approval in the United States and has entered the component manufacturing phase.

BWRX-300 (USA / Canada)

A simplified boiling water reactor with a gross electrical output of ~ 300 MWe. It uses natural circulation and reduced system complexity to shorten construction schedules and lower capital costs. The design is currently in the Detailed Design phase with several countries considering deployment.

SMART (South Korea)

A 107 MWe integral PWR designed for electricity and heat production. It incorporates inherent and passive safety systems, making it suitable for countries with smaller grids or limited infrastructure. The design has undergone standard design approval in Korea.

If desired, 3D-printable data for constructing a small modular reactor can be downloaded from the Free Download / 3D Printing section.

CAREM-25 (Argentina)

A 25—30 MWe integral PWR currently under construction. All primary components are located inside a single reactor pressure vessel, improving safety and reducing external piping. CAREM-25 is intended as a demonstration unit for future larger variants.

ACP100 / Linglong One (China)

A 125 MWe PWR using forced circulation in the primary loop. ACP100 is notable as one of the first SMRs to enter actual construction. It targets coastal regions, islands, and industrial sites requiring medium-scale, reliable power.

HTGR-type SMRs (High-Temperature Gas-Cooled Reactors)

High-temperature gas-cooled reactors use helium coolant and graphite moderation, enabling outlet temperatures suitable for cogeneration, industrial heat, hydrogen production or desalination.

In the modular pebble-bed high-temperature reactor HTR-PM, each reactor together with its steam generator forms a Nuclear Steam Supply System (NSSS) module, and several such modules are connected to a shared turbine.

HTR-PM (China)

A twin-module pebble-bed HTGR delivering 210 MWe to a single turbine. The plant is in commercial operation, with continuous online refuelling using spherical TRISO fuel pebbles. Its high outlet temperature enables efficient electricity generation and industrial applications.

Xe-100 (USA / South Africa)

An 80 MWe modular pebble-bed HTGR using helium coolant and graphite moderator. Designed for cogeneration, district heating and desalination, it offers flexible deployment in multi-module configurations.

GTHTR300 (Japan)

A 300 MWe high-temperature gas-cooled reactor using helium coolant and graphite moderation. It provides very high outlet temperatures suitable for cogeneration and hydrogen production. TRISO fuel and passive safety features ensure stable, high-temperature operation.

Liquid Metal-cooled Fast Spectrum SMRs

Fast reactors cooled by liquid metals such as lead or sodium operate at low pressure and high temperature, enabling efficient heat transfer, high fuel utilisation and the potential for closed fuel cycles.

Drawing of the General Electric-Hitachi Power Reactor Innovative Small Module (PRISM), a liquid-metal fast reactor.

BREST-OD-300 (Russia)

A 300 MWe lead-cooled fast reactor of pool-type configuration, currently under construction. It uses mixed nitride fuel and allows refuelling every 3—6 years. The design supports a closed fuel cycle and long-term sustainability.

ARC-100 (Canada / USA)

A 100 MWe sodium-cooled pool-type fast reactor with extremely long core life, requiring refuelling only after 20 years of operation. The design is in preliminary development and aims for high reliability and minimal maintenance.

SVBR-100 (Russia)

A lead-bismuth-cooled fast SMR derived from submarine reactor experience. Producing around 100 MWe, it features a compact pool-type design and inherent safety characteristics associated with heavy-metal coolant systems.

Molten Salt SMRs

Molten-salt reactors operate at low pressure and high temperature, offering inherent safety characteristics and flexible fuel cycle options, including the potential use of thorium.

Solid and liquid phases of FLiBe salt, a lithium-beryllium fluoride mixture used as coolant or fuel salt in molten salt reactor designs.

IMSR-400 (Canada)

The Integral Molten Salt Reactor is a 195 MWe design using molten-salt fuel in a sealed “core unit” that is periodically replaced as a whole. It emphasises operational simplicity, inherent stability and rapid deployment.

SSR-W / SSR-U (Moltex Energy, Canada/UK)

The Stable Salt Reactor family uses molten salt as coolant and solid fuel assemblies (SSR-W) or fuel dissolved in molten salt (SSR-U). The designs operate at low pressure and high temperature, offering robust passive safety and potential to use recycled nuclear fuel.

ThorCon (USA / Indonesia)

A modular, shipyard-manufactured molten-salt reactor using liquid fuel. Components are replaced in large sealed units, simplifying maintenance. ThorCon targets cost-effective deployment in emerging markets and island nations.

Microreactors

Microreactors provide very small-scale nuclear power for remote regions, industrial facilities or defence applications. They emphasise transportability, autonomy and long refuelling intervals.

eVinci (Westinghouse, USA)

A heat-pipe cooled, a TRISO fuelled 5 MWe microreactor, designed for eight or more full-power years before refuelling. It is factory-built and can be shipped in a standard container, enabling rapid deployment to remote sites with minimal infrastructure.

Aurora (Oklo, USA)

A compact liquid metal cooled fast microreactor intended for long-duration autonomous operation. The design focuses on minimal staffing requirements, flexible siting and off-grid power supply.

U-Battery (UK)

A 4 MWe helium-cooled microreactor suitable for industrial heat, process energy and small-scale electricity production, offering very compact footprint and high-temperature output.

Future Outlook / Research Directions

Small Modular Reactors are expected to play a growing role in future low-carbon energy systems as countries seek flexible, dispatchable and scalable sources of clean power. Several designs are progressing through licensing, demonstration or early construction, with the first commercial deployments anticipated in the 2030s. Continued development focuses on reducing capital costs through serial manufacturing, expanding non-electric applications such as industrial heat and hydrogen production, and integrating SMRs with renewable energy systems and emerging energy infrastructures.

Representatives of the NRC receive NuScale’s application for the certification of its small modular reactor design.

Research priorities include advanced fuels with longer lifetimes, improved materials for high-temperature operation, enhanced passive safety systems, and digital technologies for autonomous or semi-autonomous operation. International collaboration on regulatory harmonisation is also becoming increasingly important to streamline licensing and facilitate global deployment. As these technological and regulatory advances converge, SMRs are positioned to complement both large nuclear reactors and variable renewable sources, offering a versatile pathway toward deep decarbonisation and robust energy security.