The Energy Use of the Photovoltaic Effect

7 min read

Photovoltaic Effect

The photovoltaic effect is a phenomenon where electromotive voltage is created in a material by its exposure to radiation of specific wavelengths. In the case of light, radiation is in fact photons, the basic particles of light. Depending on their energy, which is determined by wavelength, photons have the ability to eject electrons from the crystal structure of a material.

In practice, semiconductors are used, most commonly silicon. The minimum energy needed to eject an electron from the crystal structure is 1.12 eV (corresponding to a wavelength of 1,105 nm). Photons with energies higher will eject electrons while photons with lower energies will not.

The ejection of electrons in semiconductors is a result of photons being absorbed by the material passing their energy to the atoms of the crystal structure which in turn eject the electrons. The empty space left by the electron is called a hole and has properties of a positively charged particle.

History

The photovoltaic effect was first observed by the French physicist Alexandre Edmond Becquerel in 1839. In 1904, the physics of this effect was described by Albert Einstein who received the Nobel Prize for this achievement. The first practical photovoltaic solar cell, with an efficiency of 6%, was made of crystalline silicon and produced by the Bell laboratories in 1954.

Solar Cells

Solar cells (or photovoltaic cells) are the basic building elements of any solar system that transforms solar radiation directly into electric energy. Solar cells exploit the photovoltaic effect in semiconductors.

A solar cell is basically a P-N junction of a larger semiconductor diode. The lower P-layer is most frequently crystalline silicon doped with boron. The top N-type semiconductor layer is usually silicon doped with indium. At the interface of the layers, a P-N junction is created which only allows electrons to pass from the P-layer to the N-layer. Electrons that are knocked loose (ejected) by impacting photons accumulate in the top N-layer and create an electric potential of approximately 0.6 V between the layers. By connecting suitable electrodes, this potential can be used to create current.

Presently, these three types of solar cells are most common:

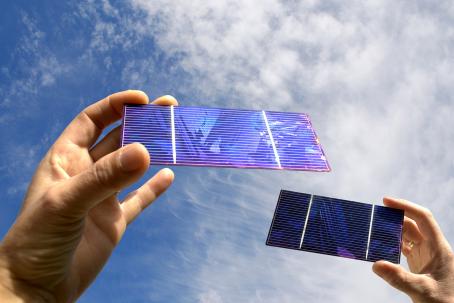

Monocrystalline solar cells

The main element of monocrystalline solar cells is a silicon plate made from a slice of a monocrystal. The monocrystal itself is grown from molten silicon into the form of cylinders. Its structure is continuous, unbroken and pure. The silicon slices are clipped to the right size and shape required for the cell (usually 156 × 156 mm). The plates are dark or even black and often octagonal. The efficiency of monocrystalline solar cells lies between 14 and 20%.

Video: 3D model of the construction with photovoltaic panels. Photovoltaic panels are placed even on the separate simple constructions that monitor the Sun position and ensure straight incidence of solar rays on the panels.

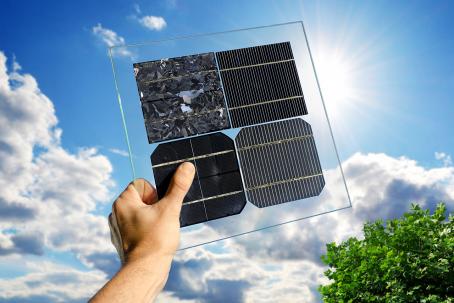

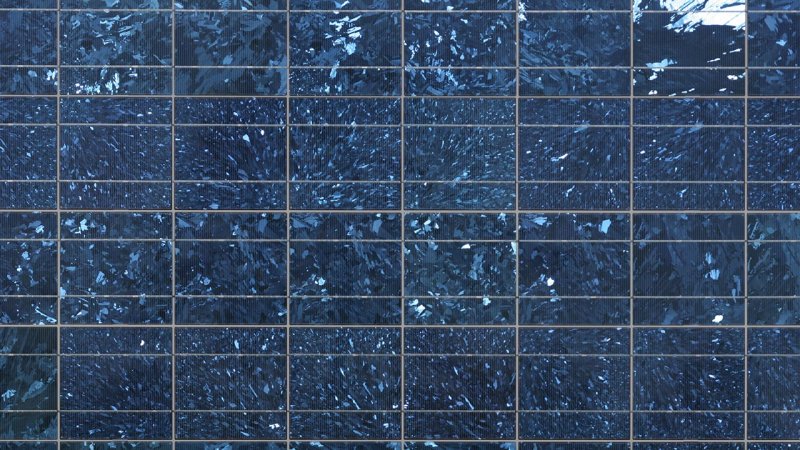

Polycrystalline solar cells

The main element of polycrystalline cells is a polysilicon plate. Polysilicon is a material consisting of small silicon crystals. The production of a polysilicon rod, from which the plates are sliced off, is simpler and cheaper than monocrystal production. The plate is usually square, dark-blue with visible outlines of individual crystals. Polycrystalline solar cell efficiency lies between 12 and 15%. This type of cell is the most widely used. They absorb dispersed light better and are not as sensitive to deviations from a southerly orientation.

Thin film solar cells

The main element of thin film solar cells is a suitable substrate (like glass, plastic or stainless steel) on which a thin film of photosensitive material is deposited (e.g. amorphous silicon). Thanks to the thinness of the film, several layers can be stacked on one another each tuned for a different wavelength and thus better utilizing the solar spectrum. Thin film solar cells can be used as roof skins, hydro-insulation strips for flat roofs or as regular solar panels. They are less sensitive to directional orientation and temperature and they work well even under unfavourable light conditions. The efficiency of thin film solar cells is only 8 to 10% and therefore, twice the area of monocrystalline cells is needed to get the same output. Amorphous silicon has an efficiency of 6—9%, cadmium-tellurium has 9—11% and CIS (copper-indium-diselenium) and CIGS (copper-indium-gallium-diselenium) have 10—12%. Since much less expensive material is needed for their production, thin film solar cells can be produced much more cost-effectively than conventional silicon cells. About 10—15% of all solar cells are thin film cells.

Solar Panels

Video: 3D model of the solar panel.

The voltage of one solar cell is too low to be of direct use. Therefore, solar cells are clustered into larger units which are called solar panels. The cells can be connected either in series for higher voltage, or in parallel for higher amperage, or both, to achieve optimum working parameters. Usually solar panels are designed to produce electricity at a certain voltage such as 12 or 24 volts. The amperage is directly proportional to the amount of light falling on a panel.

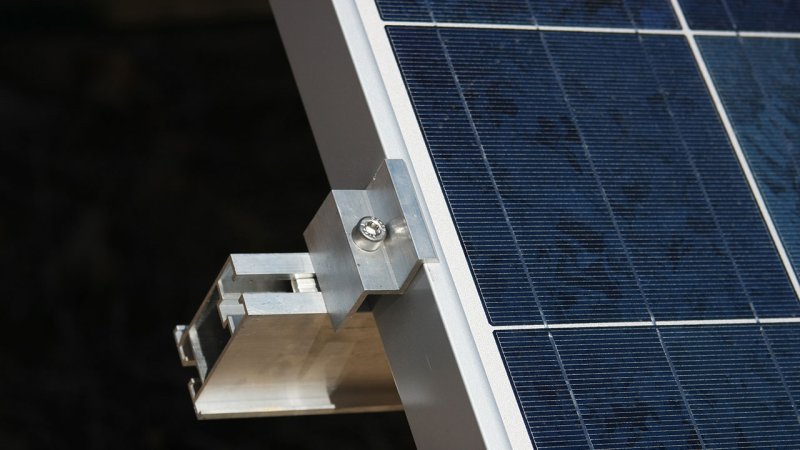

The bottom part of a solar panel is a stiff supporting board fitted into a frame. The top part is a transparent protective cover, e.g. hardened, polished glass.

The optical properties of the protective cover play a major role in determining the efficiency of a solar panel since only certain amounts of light can pass through and can be worked with. The sturdiness is important for withstanding storms and hail. Also, the panel materials will not be worn out by UV light and the climate.

The roofs of residential or industrial buildings are popular places for installing solar panels but panels can, of course, be attached to simple supporting structures that can stand anywhere. To increase efficiency, Sun tracking systems may be added that ensures there is the right angle between sunbeams and the panels at all times. The life-span of solar panels is approximately 30 years.

The most powerful mass-produced solar panels can supply more than 140 W/m2.